Cooler Cleaning Basics

Why you Need to Clean your Cooler

The Hot Flush machine pumps heated cleaning fluid through the oil cooler, with the direction of flow instantly reversing every 3 seconds for a quarter of a second.

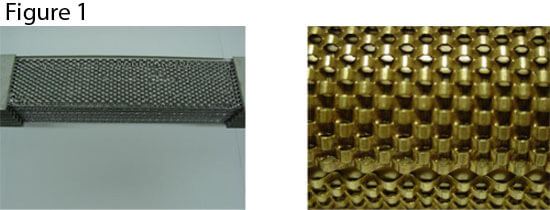

Many times coolers get overlooked, because most people don’t understand the intricacies of them. A lot of technicians have never seen the inside of a cooler. Today’s coolers make for wonderful heat exchangers, but to do that they end up with thousands of little "traps" for debris to get caught in. Transmission oil molecules do not conduct heat amongst themselves efficiently, but they do conduct well with metal. So the cooler manufacturers must design coolers that makes the oil molecules make contact with metal as much as possible. This leaves us with coolers that contain many various "weave" or "honeycomb" type patterns (see Figure 1).

When the metal is heated, the small gaps in the cooler expand. When a failure happens the debris gets shot into the cooler, which is usually hot and expanded. Then the vehicle is shut off causing the cooler to cool and the debris to become bound into the "traps" as they shrink. Typically the transmission gets rebuilt and the cooler gets flush ed of some of the loose debris with a cold solvent flusher. When the cooler is returned back to normal operating temperatures, the metal expands again releasing the debris that was bound in the cooler. More then likely, this means warranty work.

Many Ford and Chrysler coolers today have a thermal bypass valve that does not open or redirect ATF until it gets warm enough to need the cooler or the auxiliary cooler. So if you are flushing cold, you may unknowingly be flushing only part of the cooling system. Then there is Chrysler’s in line drainback valve to deal with. To properly flush the cooler and the lines this valve must be temporarily removed or bypassed.

There are many cooler flushers on the market today, but anybody that truly understands cooler contamination will tell you that there are certain things that must be done for a quality cooler flush.

- Transmission fluid must be used and it must be heated to at least 180 degrees.

- There must be some sort of reversing action (simple pulsating pumps are not sufficient; the pulsation dissipates by the time it reaches the cooler).

- You must have some way of determining when the cooler is done giving up material.

With a closed filter, you are only guessing that the cooler is clean.

There are no risk-free alternatives to flushing the cooler either. In-line filters will eventually plug then the bypass will open, making the filter completely ineffective. Replacing the radiator cooler or adding an external cooler can be very expensive and time consuming, plus new coolers have many times been found to have debris in them from the factory (See figure 2).

The test drive may run smooth, but then the vehicle returns a week later with valve body issues. The pan gets pulled only to discover converter material. The converter gets sent back and replaced. The unit gets reassembled and sent down the road. There may not have been anything wrong with the fi rst converter. T he material found in the pan may have been from the original converter not the new o ne. It was debris caught in the cooler from the first failure (See Figure 3). Through our own research, we’ve found that up to 30% of the time the converter takes the blame for a contaminated cooler.

Another thing people fail to recognize is that no matter how thorough a shop is about cleanliness of parts and coolers, it's not necessarily enough. Converters can still be an issue. It doesn't matter how clean the system is if you use a converter that isn't as clean as the rest of the system. Many remanufactured converters come with various contaminants and even rust particles just waiting to make a valve stick. Torque converters are a prime scenario for the old saying "You get what you pay for."

We’ve been talking about the money that will be saved with properly flushed coolers. Now let’s talk about the money that will be made. You will now be able to work on more units instead of dealing with warranties. Don’t forget, you can also charge for a quality flush. You tell the customer "I’m giving you a warranty on this transmission and you have a cooler full of material that may make your new transmission fail. We can do one of two things: either we can replace your radiator cooler for (example $300) or we can flush your cooler for $90." If you have a fully automated flusher that $90 is almost all profit—while your technician can be earning you more money doing something else.

Get a Free Consultation

Hot Flush uses a patented process that cleans in a truly superior way. It removes the smallest of particles. It works incredibly fast. It is easy to use. We are here to answer any questions you may have about the machine or how it works. If you are tired of dealing with failures after a fresh build, hot flush can solve your contamination problems. Our patented process works better than anything you’ve ever tried. Guaranteed.

There are many different real-life examples we can share with you if you decide to get in contact. Our previous work and results will help illustrate why Hot Flush delivers a cleaning ability you need for your important application. In addition to a great functioning oil cooler / heat exchanger, Hot Flush is extremely cost effective—able to pay for itself and save you money well into the future. It is a simple, affordable, and effective solution we would be happy to tell you more about!